Catalyst development via modern tools

Catalyst development is one of the key elements in modern industry. As industrial leaders and innovation startups strive for efficiency, catalyst optimization, modification and development become the most important field of research. Efficient catalyst choice or development lead to huge improvements in production times, energy savings and profit margins. That brings us to the question: is catalyst development an easy task? Is it a quick process? What is the success ratio? Just talking a look at major industrial processes like ammonia production or Fluid Catalytic Cracking reveals that catalyst development is nothing but an easy task.

Catalyst development and modification has passed through different stages through history; from observation and intuition in ancient Greece and Egypt, to primitive lab testing in middle ages, to organized attempts in industrial era and finally today to prediction of properties and effects through simulation tools. Catalytic action can be explained in terms of lowering activation energies, but the deep understanding of their action is hidden in the ways that they actually lower those reaction activation energies.

If there was just one mechanism of lowering activation energies, catalyst development could be much faster and straight forward. Unfortunately, nature does not work like that; interactions between atoms and molecules in a chemical reaction depend on so many parameters that one has to solve a very complex system of equations, interactions and 3D maps to clearly identify obstacles and by-passes. When atoms and molecules interact, everything matters; electronic charges, electron density distributions [4D, time and space], molecular shapes [3D], chemical environment, temperature, pressure, and others.

Sometimes, all it takes for a reaction to be promoted is a medium that can bind two molecules and bring them together as a bridge. Some other times, a coordination scheme is required, where a center [usually a metal atom] can coordinate a number of reactant atoms or molecules around it and supply the necessary geometry and intermolecular distances for reactions to start. In other cases, a catalyst acts as a building block base [as in PE production]. For the lab chemist, the researcher, the R&D engineer, all of these cases can prove beyond their capabilities. If you just compare the number of catalysts developed vs the reactions at hand you will face the truth: catalyst development requires skills, tools and the will to adopt to new technologies.

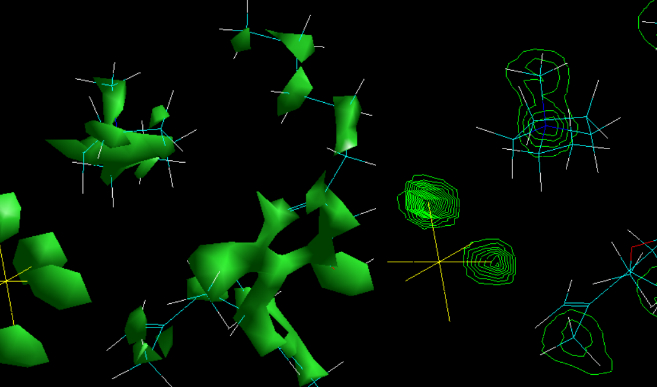

Modern tools especially in the field of computational chemistry have allowed for faster and accurate prediction of catalytic properties and catalytic reaction paths. Via such tools one can build a series of catalyst models and ‘test’ them [screening process] against reaction systems. This is a very fast and efficient process that is also used in solvent screening projects. Scientists world wide create such 3D models of potential catalysts, derive all the necessary properties [including physical, chemical and electronic] and incorporate them into dynamic reaction systems. All energy changes are being monitored and recorded allowing for instant identification of reaction paths. All interactions are clearly visible and understood thanks to Graphical User Interfaces that most computational chemistry tools use. Just as a simple comparison, a virtual screening of 100 catalysts can take place within three to fifteen hours [depending on the computational power at hand] whereas the same screening would require weeks in a lab. In addition to that, the virtual screening would cost zero in comparison to thousands of dollars in the lab for reactants, lab time, consumables and other related costs.

In conclusion, developing and modifying catalysts is of the highest importance for modern industry. Successful development, investigation or modification of catalysts requires the use of state of the art computational tools.

Get deeper insight on latest catalyst developments and best selection criteria, checkout this online training on Catalyst selection for excellent formulations.