The Science of Twin Screw Extrusion Machine; basic understanding to start with twin screw extrusion

Twin screw extrusion machine is a widely used industrial process for producing a wide range of products from food, plastic, and chemical industries. The process is based on the principle of plasticization and homogenization of the raw material in the presence of heat and pressure. The twin screw extruder is a key component in this process as it plays a crucial role in determining the final product quality and efficiency. This article aims to provide an insight into the science behind twin screw extrusion and its applications in various industries.

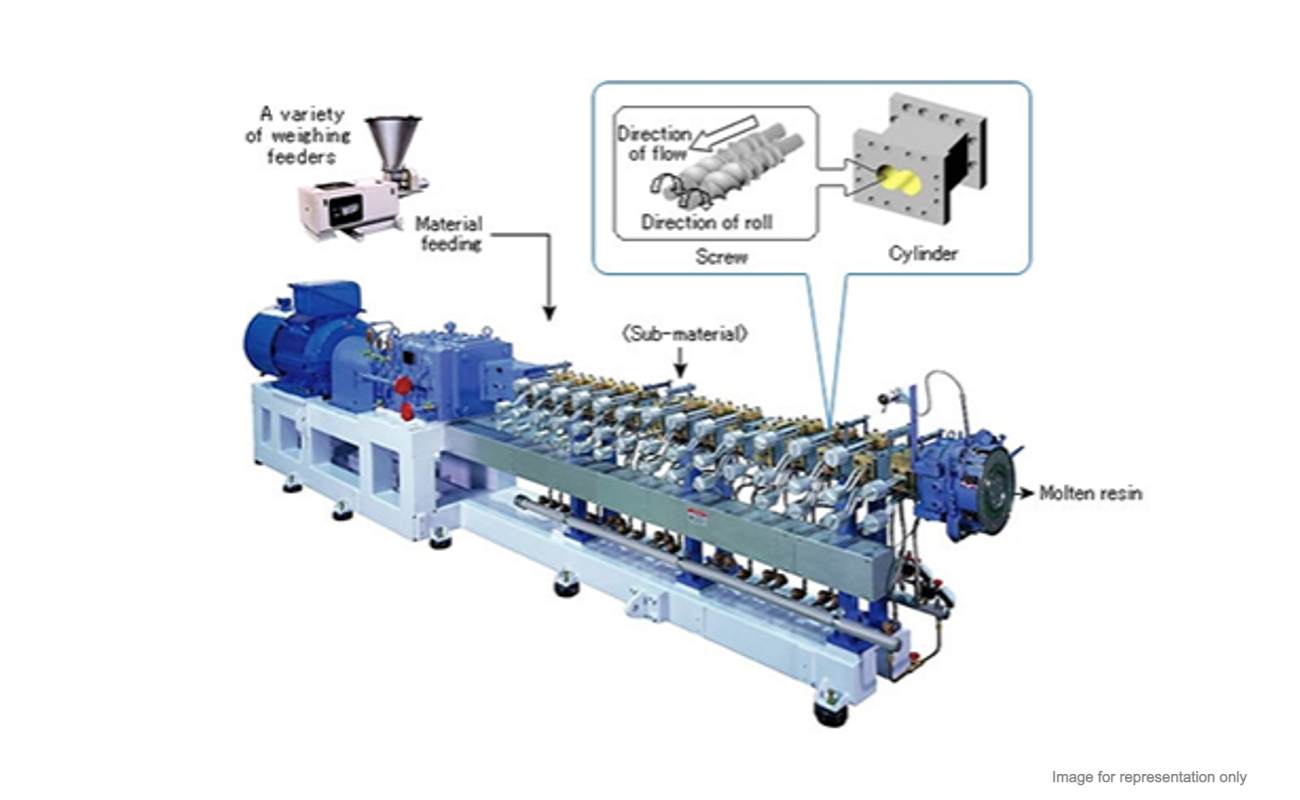

Working Principle

The twin screw extrusion machine consists of two parallel screws that rotate in opposite directions and are housed inside a barrel. The raw material is fed into the barrel through a hopper and is transported through the screws towards the end of the barrel. The screws are designed in such a way that they compress and heat the raw material to a specific temperature range, thus converting it into a homogeneous mixture. This mixture is then forced through a die and is cooled to form the desired product. The twin screw design provides a high degree of mixing and kneading action, which enhances the plasticization and homogenization of the raw material.

Types of Screws

There are different types of twin screw extruders, each with a specific design to meet the requirements of a particular application. The most common types of screws are co-rotating, counter-rotating, and intermeshing.

Co-rotating Screws: The co-rotating screws have the same direction of rotation and are used for applications that require high mixing and kneading action.

Counter-rotating Screws: The counter-rotating screws have opposite directions of rotation and are used for applications that require high compression and shear forces.

Intermeshing Screws: The intermeshing screws have a specific design that allows for maximum interaction between the screws and enhances the plasticization and homogenization of the raw material.

Applications of Twin Screw Extrusion Machine

The twin screw extrusion machine is used in various industries such as food, plastic, and chemical industries, among others. The following are some of the applications of twin screw extrusion technology:

Food Industry: The twin screw extrusion machine is used in the food industry for the production of breakfast cereals, pasta, snacks, and pet food. The high degree of mixing and kneading action provided by the machine helps in enhancing the texture and flavor of the final product.

Plastic Industry: The twin screw extrusion machine is used in the plastic industry for the production of pipes, sheets, profiles, and films. The machine provides the desired level of plasticization and homogenization of the raw material, which is essential for the production of high-quality plastic products.

Chemical Industry: The twin screw extrusion machine is used in the chemical industry for the production of polymers, resins, and additives. The machine helps in controlling the reaction kinetics and provides a high degree of homogenization, which enhances the final product quality.

Let's conclude..

The twin screw extrusion machine is a versatile and efficient process that has found widespread applications in various industries. The science behind the twin screw extruder is based on the principle of plasticization and homogenization of the raw material in the presence of heat and pressure. The different types of screws and their specific designs allow for a wide range of applications, including food, plastic, and chemical industries. With the continuous development and innovation in the field of twin screw extrusion technology, the machine is expected to play an even more critical role in shaping the future of various industries.

Don't forget to access this expert's recommended training on twin screw extrusion to sharpen your skills: Twin Screw Extrusion; Set-up And Optimizing Process Parameters For Performance And Cost Saving