Combination of Techniques (FTIR+DMA) can answer most of the characterisation related queries

Query No. 1

I typically scan through a composite material comprised of a PVC film coated onto a Polyester Textile. Generally scanning the thin 8-15mil thick PVC film layer. Does having the Polyester textile on the back influence results?

Answer: We suppose that the PVC will not mix together with the polyester textile when it is scanned. So, you scan through the PVC, which is +/- a film. Possible is the film thickness different at places where the PVC touches the polyester textile. Possible is the textile fibre also thin coated at the back side. You scan also partly through the polyester textile. The result will be a summation of the two spectra. Possible you get some special interference effects. I must admit I do not have experience with that. You scan it most likely to determine the thickness of the PVC coating? Possible you can make a regression curve by using different peaks. The PVC you are using is probably also plasticized. This makes that you will have three components: polyester, pvc and the plasticizer...

Query No. 2

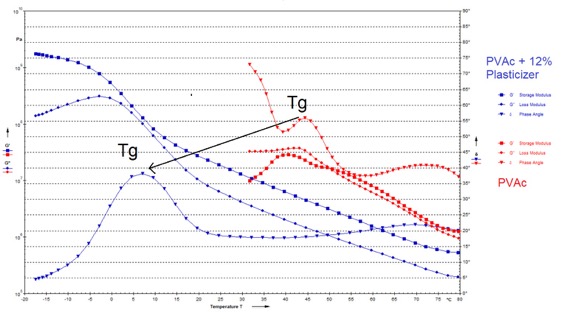

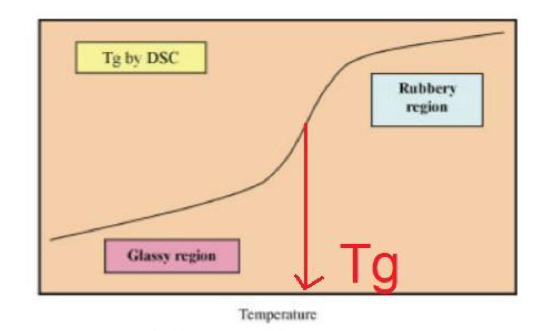

How Tg is measured and how it can relate with the measurement I do on DMA or the Rheometer?

Answer: When you receive a Technical Data Sheet from your supplier, they mention in most cases the Tg measured by DSC (e.g. ISO 16805). The Cp-value of a material changes when there is a transition from rubbery to glassy state:

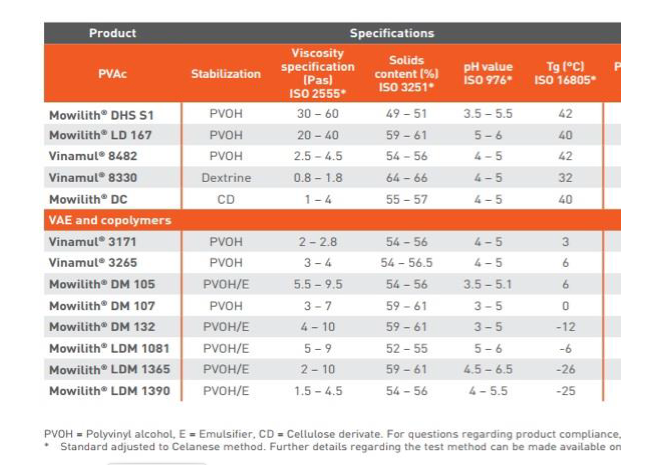

This is an example of a table , you may receive from your supplier :

So, see you can always try out the combination of different characterisation techniques for the quicker analysis and faster product development. You can also checkout this experts recommended on-demand training Combined study of FTIR+DMA to improve your product development efforts.