3D Printing Technology Applications: What's Happening & What More To come?

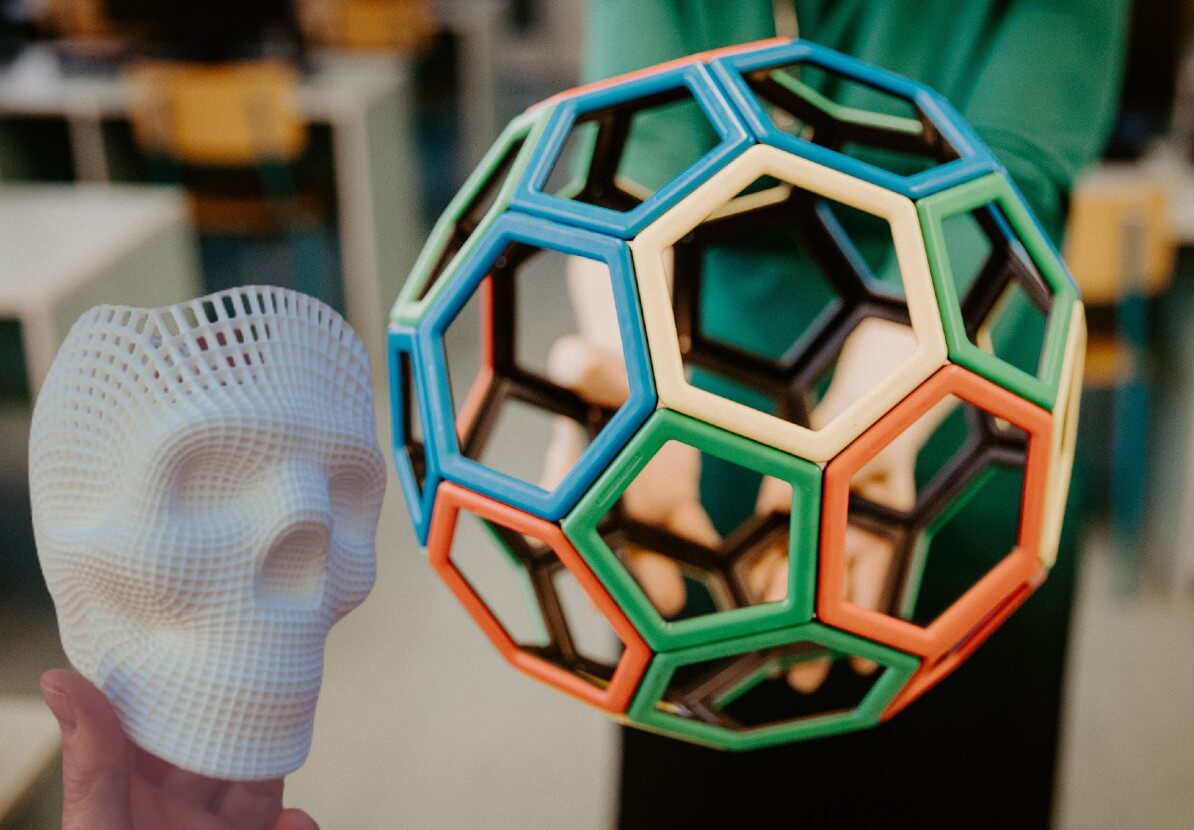

3D printing (Additive manufacturing) translates computer-aided design (CAD) virtual 3D models into physical objects. In more simpler terms it is a very popular form of manufacturing, used to create objects from digital designs, by layering resin to build a 3D component.

Little Bit About The History:

Introduced during the 1980s to serve the highly specialized needs of model making and rapid prototyping, 3D printing has emerged as a versatile technology platform for computer-assisted design (CAD) and rapid manufacturing. It gave freedom to produce customized parts from metals, ceramics, and polymers without the need for molds or machining typical for conventional formative and subtractive fabrication. One of the many reasons behind the success of 3D printing is that it allows the production of 3D structures with high shape complexity.

Current Solutions:

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology. Apart from FDM and metal 3D Printing technologies, resin 3D Printing remains one of the most widely used techniques for producing high-quality 3D prints. Today 3D printing is being used in almost all industries you could think of.

Applications of 3D Printing Technologies

3D Printing applications cover various sectors from education to industry, and the whole value chain from prototypes to spare part management. Applications are emerging almost by the day, and, as this technology continues to penetrate more widely and deeply across industrial, maker and consumer sectors, this is only set to increase. 3D printing is an enabling technology that encourages and drives innovation with unprecedented design freedom while being a tool-less process that reduces prohibitive costs and lead times. Components can be designed specifically to avoid assembly requirements with intricate geometry and complex features created at no extra cost. We have to agree that in this technology sector as of today it is just beginning and true potential of 3D printing is yet to come.

LET'S GO THROUGH SOME IMPORTANT APPLICATION AREAS OF 3D PRINTING TECHNOLOGY

Medical and Dental

It is the sector with huge potential for growth, due to the customization and personalization capabilities of the technologies and the ability to improve people’s lives as the processes improve and materials are developed that meet medical grade standards. In addition to making prototypes to support new product development for the medical and dental industries, the technologies are also utilized to make patterns for the downstream metal casting of dental crowns and in the manufacture of tools over which plastic is being vacuum formed to make dental aligners.

The technology is also taken advantage of directly to manufacture both stock items, such as hip and knee implants, and bespoke patient-specific products, such as hearing aids, orthotic insoles for shoes, personalised prosthetics and one-off implants for patients suffering from diseases such as osteoarthritis, osteoporosis and cancer, along with accident and trauma victims. Technology is also being developed for the 3D printing of skin, bone, tissue, pharmaceuticals and even human organs.

Aerospace Industry

Aerospace Industry was one of the earliest adopters of 3D printing technology with initial use recorded back in the late 1980’s. Nowadays it is still considered the industry which has the highest rate of adoption of 3D printing technologies. Large, complex parts and fully dense components are easily manufactured with reduced lead time through the integration of 3D printing in aerospace manufacturing processes. The ability to 3D print intricate castings directly from 3D CAD files which can be modified quickly to accommodate design changes provides greater opportunities to design parts with aerospace applications.

Aerospace applications include the creation of castings for complex gear cases and covers, fuel tanks, transmission housings, components requiring draft free walls, lightweight engine parts, and structural hinges. Metal 3D printing systems can also directly print batches of small metal parts at scale leveraging metal injection moulding powders compatible with use in aerospace manufacturing. High profile users include GE / Morris Technologies, Airbus / EADS, Rolls-Royce, BAE Systems and Boeing.

Automotive Industry

The automotive industry has been at the forefront of pioneering the applications of 3D printing technology in manufacturing. The rate of adoption of 3D printing technology across the industry has grown substantially over the last few years. Many automotive companies have followed a similar trajectory to the aerospace companies. They are using the technologies for prototyping applications, but also developing and adapting their manufacturing processes to incorporate the benefits of improved materials and end results for automotive parts.

Many automotive companies are now also looking at the potential of 3D printing to fulfil after sales functions in terms of production of spare/replacement parts, on demand, rather than holding huge inventories. One future application is the use of 3D printing to manufacture more and more of the actual vehicle parts, this allows parts to be customised to end-user requirements.

Jewellery Industry

For the jewellery sector, 3D printing is a great deal of interest, based on how 3D printing can, and will, contribute to the further development of this industry. From new design freedoms enabled by 3D CAD and 3D printing, through improving traditional processes for jewellery production all the way to direct 3D printed production eliminating many of the traditional steps. Let’s see some examples of 3D printing technology in jewellery industry:

-> Design communication and demonstration: make enough models rapidly for assessment by 3D printing equipment at the beginning of design stage of product.

-> Meet the customization demand of personalized products: with the characteristic of high efficiency, 3D printers could help buyers make quick responses to the demand of customer’s customization and seize the high-end market, such as jewellery customization.

-> Assembly test and function test: realize the targets that function of product is improved, cost of production is reduced, quality is better and market acceptance of product is promoted.

Architecture

Architects, Engineers, and Construction (AEC) professionals understand the paramount importance of accurate and tangible scale models. 3D printing for architects empowers them to easily create complex, accurate and durable scale models quickly and cost-effectively. 3D printing offers a relatively fast, easy and economically viable method of producing detailed models directly from 3D CAD, BIM or other digital data that architects use. Many successful architectural firms now commonly use 3D printing (in house or as a service) as a critical part of their workflow for increased innovation and improved communication.

Fashion Industry

3D printed dresses can potentially be as revolutionary as the sewing machine. Not only 3D printing, 3D technology itself is changing the entire value chain in the apparel industry from design and prototyping to the finished product and its delivery. 3D printed accessories including shoes, head-pieces, hats and bags have all made their way on to global catwalks. Once apparel makers adopt the new technologies, more 3D printed clothing will permeate through to the masses. 3D printed clothing is not always the entire garment structure. Sometimes 3D printed material is used as an adornment or a feature like buttons or cuffs.

3D printed fashion allows designers to innovate faster. Lead times can get reduced drastically. Wearable clothing can be made with very few geometrical constraints. The digital element of 3D printing removes multiple limitations which designers faced in the physical world. The process of adoption for 3D printed clothing could be gradual. It could take a few years before we start seeing 3D printed clothing becoming more common.

Food Industry

There is immense potential in this newly emerging technology to change the face of the food industry. From pizza to drinks, this technology is being adopted by food industry professionals to make a mark in producing distinctive edibles. One of the most advanced 3D print technologies allows food experts to pre-load recipes that can then be customised in shape, colour, texture, flavour or nutrition.

Initial forays into 3D printing food were with chocolate and sugar, and these developments have continued apace with specific 3D printers hitting the market. Some other early experiments with food include the 3D printing of 'meat' at the cellular protein level. More recently pasta is another food group that is being researched for 3D printing food. Looking to the future, 3D printing is also being considered as a complete food preparation method and a way of balancing nutrients in a comprehensive and healthy way. It will radically change food-production practices and embed creativity into culinary creations in a sustainable and nutritious manner.

The future of 3D printing technology in the food industry is looking stronger than ever. However, although there has been a growing demand for it, one of the biggest obstacles to its use is cooking the final product.

Consumers Goods & Packaging Industry

Consumer goods companies are taking the plunge into 3D printing, to provide more customer-centric services and products cost-effectively. 3D printed consumer product design approach aims to empower manufacturers by enhancing collaboration, saving time in prototyping and thus reaching the market and the consumers faster. The way you design, produce, and package consumer goods contributes to your success in the market. However, traditional design and prototyping processes are costly and time-consuming. Competitive edge over competitors is a crucial factor for any company, and they spend billions and billions and billions for this advantage. Let’s see some benefits of 3D printing for consumer goods companies:

-> 3D printing makes it possible to produce prototypes much faster than with traditional manufacturing techniques, like CNC.

-> 3D printing allows companies to achieve maximum design freedom when making complex geometries, impossible to manufacture by conventional processes.

-> Customisation remains one of the major benefits of 3D printing for consumer goods. 3D printing creates new customisable possibilities because it doesn’t require expensive tooling changes based on individual specifications.

-> Thanks to 3D printing which can significantly reduce material waste, thereby making the manufacturing process more sustainable.

Do not forget to access the trainings Additive Manufacturing (3D Printing) technology & Additive Manufacturing (3D Printing) Combinations And Integrations broader insight into this exciting technology.