- Call: +1 850 633 2663

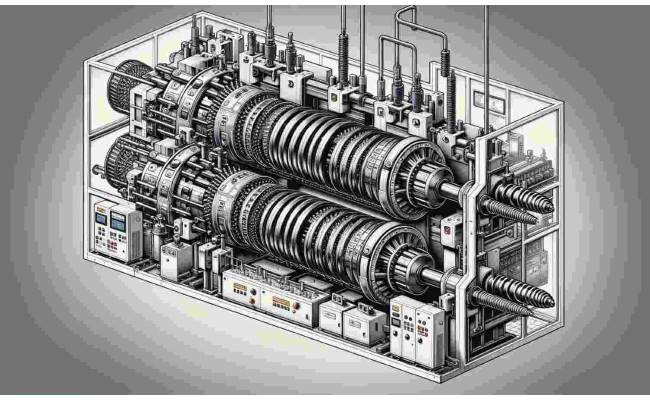

Twin screw extrusion is a sophisticated and versatile process widely used in plastic and food industries for blending, compounding, and shaping materials. Optimizing this process is crucial for enhancing efficiency, reducing costs, and improving product quality. This involves fine-tuning various parameters such as screw design, temperature control, feed rate, and material selection. By leveraging advanced technologies like computer simulation and real-time monitoring, manufacturers can achieve significant cost savings while ensuring consistent product performance. The goal is to create a more streamlined, energy-efficient operation that maximizes output and minimizes waste, leading to better resource utilization and a competitive edge in the market.

This quick training session on Twin Screw Extrusion Optimization is essential for professionals seeking to enhance their technical expertise and contribute significantly to their organization's efficiency and profitability. This training provides a deep dive into the techniques for optimizing extrusion processes, leading to substantial cost savings and improved product quality. Participants will also understand how to troubleshoot common challenges effectively. This training is invaluable for those looking to stay competitive in rapidly evolving industries like plastics processing.

This is a very useful training for the industry professionals in particular;

- R&D chemists, formulators, scientist, new product developers

- Technical service managers, lab managers, product managers

- Professionals from adhesives and related raw-materials area

- OEM and brand owners

6 reviews