- Call: +1 850 633 2663

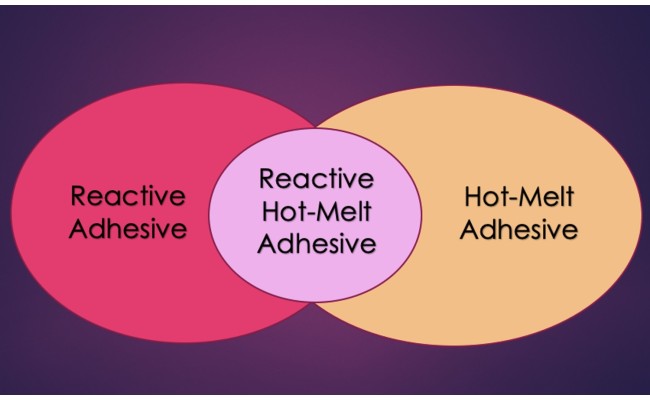

Reactive hotmelt adhesives are advanced adhesives that undergo a chemical reaction upon application, leading to crosslinking and curing. This unique characteristic results in exceptional bonding performance and durability, as covalent bonds form between the adhesive and the substrate. Advanced adhesive formulators can tailor the formulation to achieve desired open and set times, crucial in manufacturing processes that require specific handling times. RHMs utilize reactive components like isocyanates in polyurethane-based RHMs or epoxides in epoxy-based RHMs, initiating the crosslinking reactions that form a three-dimensional network within the adhesive matrix. RHMs boast outstanding resistance to environmental factors, making them ideal for demanding applications in industries like automotive, aerospace, electronics, and medical devices. Continuous research in RHMs explores new reactive components, catalysts, and curing mechanisms, as well as integrating nanotechnology to enhance mechanical and barrier properties. As an advanced formulator, understanding the complex chemistry and formulation principles of RHMs empowers you to optimize adhesive performance, create innovative solutions, and meet the evolving demands of high-performance bonding applications.

The training will impart a comprehensive understanding of reactive hotmelt adhesives. Training expert will help you to gain;

1. Unlock the Power of Reactive hotmelt adhesives: Gain a deep understanding of reactive hotmelt adhesives and their unique properties, empowering you to formulate high-performance solutions for demanding applications.

2. Master Reactive hotmelt adhesives Chemistry: Explore the science behind various RHA chemistries (polyurethanes, epoxies, acrylics) and their advantages. Learn how to leverage specific chemistries to achieve desired performance characteristics.

4. Formulate with Confidence: Develop the expertise to select the right raw materials for your specific RHA applications. This training equips you to optimize formulations based on desired performance (strength, heat resistance) and ensure seamless integration with production processes..

4. Tackle Reactive hotmelt adhesives Challenges: Understand the unique considerations associated with RHA formulations, including moisture curing and pot life limitations. This training provides strategies to overcome these challenges and formulate high-quality, consistent RHAs for successful product development.

This is a very useful industry recommended training for the adhesives and sealants industry professionals in particular;

- R&D chemists, formulators, scientist, new product developers

- Technical service managers, lab managers, product managers

- Professionals from adhesives and related raw-materials area

- OEM and brand owners

9 reviews