- Call: +1 850 633 2663

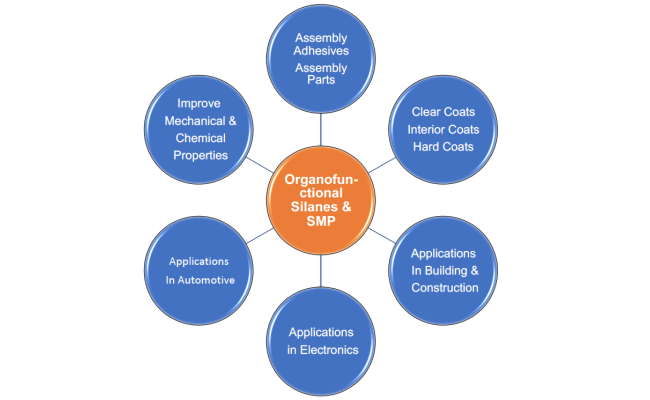

Functional silanes are key ingredients in optimizing the interphase properties that control adhesion, water and corrosion protection, strength and durability and other performance parameters. Silane reaction mechanisms were not entirely understood and there exist several theories for bonding mechanism for silanes and substrates. Nowadays formulators are incorporating organofunctional silanes in many high-performance targeted applications like adhesives and sealants, coatings, filled elastomer systems, reinforced plastics etc. to achieve key performance enhancements.

If silanes most well-known role is as adhesion promoters, they can also be used as crosslinkers to improve thermal, solvent and environment resistances, to improve mechanical properties and give them the right visco-elastic behavior once the formulation is cured. Since many silanes react readily with water, it is also possible to take advantage of this latter property to use silanes as moisture scavengers. To obtain the expected properties, it is important to thoroughly understand silane chemistry and to know the parameters that govern reactivity in the pot as well as after the application of the formulation.

Silanes functionalities like cross linking, adhesion promotions, coupling and dispersions make them formulations choice for use in numerous applications. As an illustration of the multi-functionality of silanes, we will study organofunctional silanes and silane modified technology. It is labeled as such because it consists of attaching a non-organic functionality (the silane) to an organic backbone.

Experts recommended training which every chemist/chemical engineer/formulator should have in his/her technical skills achievement. Attending this training, you will come across new ideas on how to improve existing and new formulations including sealant or adhesive that meets your expectations in terms of rheology, reactivity, mechanical properties, adhesion profile on different substrates, reactivity, shelf life.

You will be sound enough to make your working strategies to make it possible to synthesize silane-terminated polymers, and to incorporate them into a formulation of a targeted application that shows improved adhesion and UV resistance compared to fully organic equivalents. The details of a typical hybrid-based formulation will be studied, and the role of each ingredient will be described.

Recommended training for R&D chemists, developers, formulators and most important for all those industry professionals who are working with or want to start with silanes in continuation with their standard routine formulation strategies.

2 reviews