- Call: +1 850 633 2663

Products failures before achieving its lifetime are always undesired. To identify a problem that has occurred in a metal component, tooling parts or structure a failure analysis becomes necessary. If well interpreted the fracture can tell the all history behind the failure, this training focus on the practical aspects of fracture analysis. It starts approaching the investigative process of a failure analysis detailing step by step. On other hand, it is important introducing some concepts of metallurgy and how it affects the fracture modes.

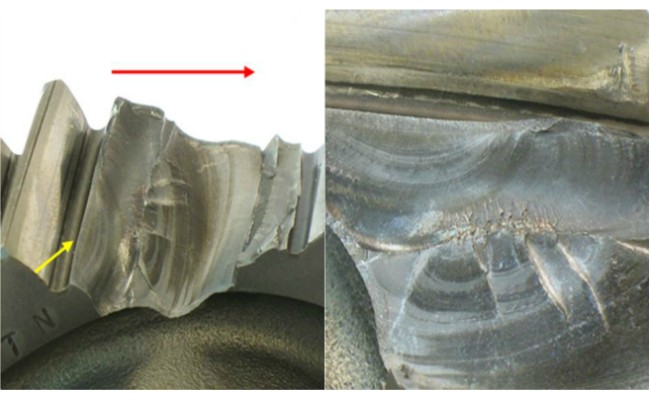

The fracture modes can be classified by the stresses which generate them. For monotonic stresses, ductile and brittle fractures are described under macro and microscopic point of view and furthermore, prevention actions are also discussed. For fatigue failure, which occurs when a material is subjected to repeated loading and unloading cycles, the approach is similar but diving into more details. Fatigue is catastrophic and insidious, occurring very suddenly and without warning, furthermore, it has been cited as one of the major causes of in-service failure throughout engineering history.The root cause analysis is much facilitated by the correct study of failure mode. This training will give you an introduction on how identify the failure mode by looking to the metal part fracture and how to remedies it.

This training is focused on practical aspect of fracture analysis in order to help failure root cause identification. It is going to be explored the differences among brittle, ductile and fatigue failures. All characteristics obtained by scanning electron microscopy (SEM), stereomicroscopy and naked eye. Fracture inspection is one of the most important actions during a failure analysis and it will be determine the appropriate corrective measures to prevent similar failures in future. However, there is a wide variety of parts types, metals, treatments conditions, loading, applications, environments, and combinations of all of these. Furthermore, there are numerous tests available to perform during a failure analysis. The correct interpretation of the results will give a truly scenario for failure understanding.

Must have training for those in production or providing technical services or consulting. Focusing on the needs of engineers, project managers, operations and analysts, mechanical design, mechanics and structures, testing and equipment fabrication, this training is a fundamentals program that offers an unique introduction to the concepts, discipline, procedures and methods..

#metalfailure #failureanalysis

0 reviews