- Call: +1 850 633 2663

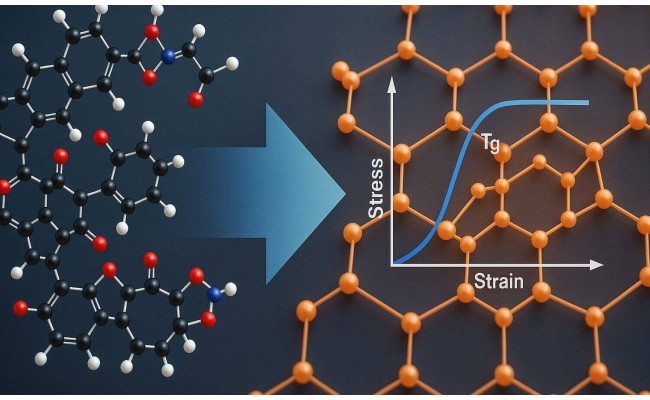

Understanding the structure-property relationships in epoxy systems is fundamental to designing high-performance materials for demanding industrial applications. Epoxy resins whether based on DGEBA, novolac, cycloaliphatic, or specialty resins exhibit unique molecular architectures that directly influence crosslinking behavior, thermal stability, mechanical performance, and environmental resistance. The selection of the curing agent e.g. amines, anhydrides, phenolics, or mercaptans further modifies the network architecture, affecting critical properties such as glass transition temperature (Tg), modulus, fracture toughness, and chemical resistance. By tailoring crosslink density, network polarity, and flexibility, formulators can achieve specific performance goals, such as improved toughness, dimensional stability, or long-term durability. Epoxy formulations are widely used in aerospace composites, electronic encapsulation, adhesives, and protective coatings, where the balance between stiffness and flexibility, or thermal resistance and chemical compatibility, is often critical.

Advanced formulation strategies now include nano-reinforcement, multi-phase toughening, and bio-based resin modifications, allowing formulators to fine-tune properties across multiple scales. Integrating predictive modeling, molecular simulations, and quantitative structure-property relationships (QSPR) also enables data-driven formulation decisions. Whether targeting CTE matching, fatigue resistance, or UV stability, understanding the epoxy structure-property landscape remains essential for developing materials that perform reliably in real-world environments.

By attending this training, you’ll sharpen your formulation edge and position yourself at the forefront of next-gen epoxy formulations. You will master to:;

1. Decode Epoxy Performance: Understand how molecular structure drives real-world properties like Tg, modulus, and chemical resistance.

2. Troubleshoot Like a Pro: Link formulation issues to root-cause structural mismatches with confidence.

3. Apply What Top Industries Use: Learn techniques trusted in aerospace, electronics, and structural adhesive design.

4. Think Beyond Trial-and-Error: Use predictive tools like Flory-Stockmayer theory and QSPR for faster, smarter formulation.

5. Advance Your R&D Edge: Turn structure-property knowledge into strategic formulation power.

This is one of those technical trainings which is highly recommended for coatings, adhesives and polymer industry professionals including:

- R&D chemist, formulators, chemical engineers

- Polymer Scientists and Materials Engineers

- Application Engineers and Technical Support Professionals

0 reviews