- Call: +1 850 633 2663

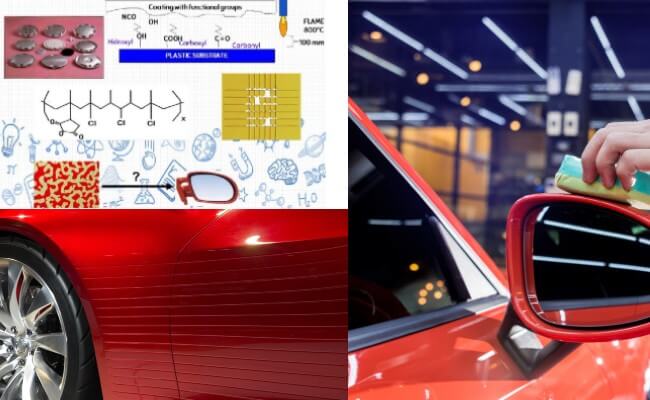

In order to improve the appearance, durability and provide aesthetic value, every substrate must be coated with systems with good adhesion. The adhesion phenomena start during the spray and coating accommodation, when must happen an adequate wetting process. A good wetting is fundamental to guarantee compatibility between the coating and substrate. After the drying or polymerization, the coating must remain coherent and strongly bonded to the respective surface, during all the service life. Among the several kinds of surfaces with special care to provide adhesion, the plastic substrates require important comments, as per example, the kind used in OEM automotive parts. The plastics usage in OEM applications continues to grow, due to their excellent features regarding flexibility, high-impact and strength. Today in automotive applications, plastics components are approximately 10% of the total vehicle weight, offering ductility, corrosion resistance and increased styling capability. This trend has been influenced, among many reasons, since to classic weight reduction, until to improve the car design, due the infinite molding possibilities.

This training will give the fundamentals of adhesion mechanisms, explaining important concepts as surface tension in liquids and solid surfaces. What means contact angle and how to measure it and the influence on coating spreading and compatibility with the substrate. In addition, cohesive and adhesive failures definition; porosity and capillarity on substrates, and its role in adhesion of coatings; how the viscosity and coatings surface tension can improve the adhesion in porous substrates; how the water can prejudice the adhesion, during the coating immersion. And also, the main adhesion promotors used in coatings technology and how they work, especially on plastic surfaces.

Adhesion is a fundamental property that any coating must have. Today with the new trends and different technologies, any coating professional must know how to improve this parameter. Sometimes, little details, like a correct adhesion promoter or a different leveling additive can make the difference between a good and a poor adhesive performance.

During the film formation, intermolecular forces and chemical bonds which provide the adhesion, depend on a short approximation range (some few angstrons), so a presence of contaminants on the interface can prejudice the final adhesion. The more a coating engineer or formulator knows about the substrate conditions, the raw-materials properties and the laws regarding the adhesion mechanisms, higher will be the reached performance.

Highly recommended training for R&D chemists, technicians, engineers, scientists, specialists and professional people from coatings and related raw-materials area. also a very useful training for spray line professionals.

3 reviews